Maxware

Laser Welding Machine Cutter, Cleaner Rust Remover 2000W Fiber laser 4in1 Welder (Free Shipping)

Laser Welding Machine Cutter, Cleaner Rust Remover 2000W Fiber laser 4in1 Welder (Free Shipping)

Impossibile caricare la disponibilità di ritiro

Shipping is Free for Orders to 48 Contiguous States. Tax included

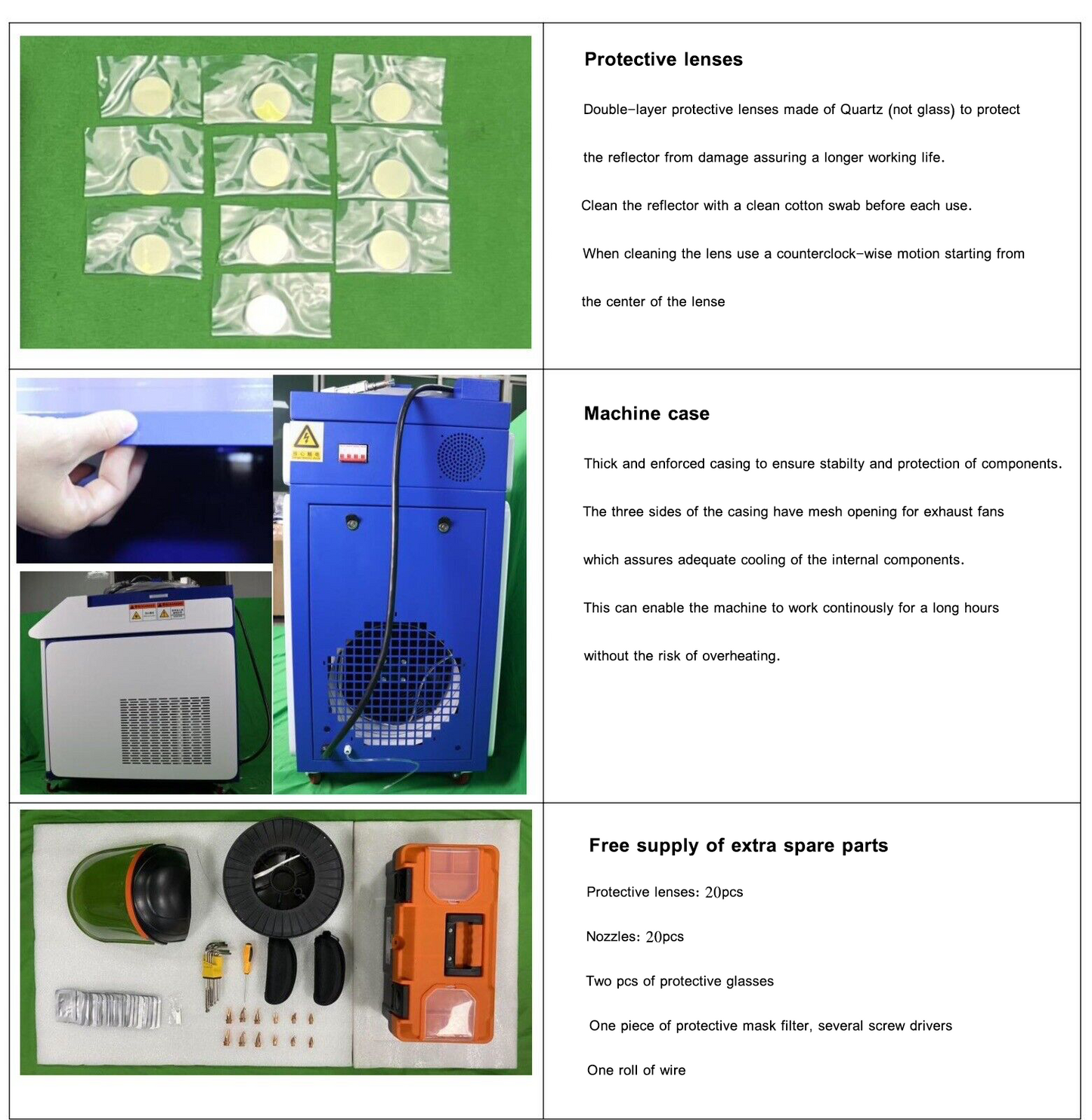

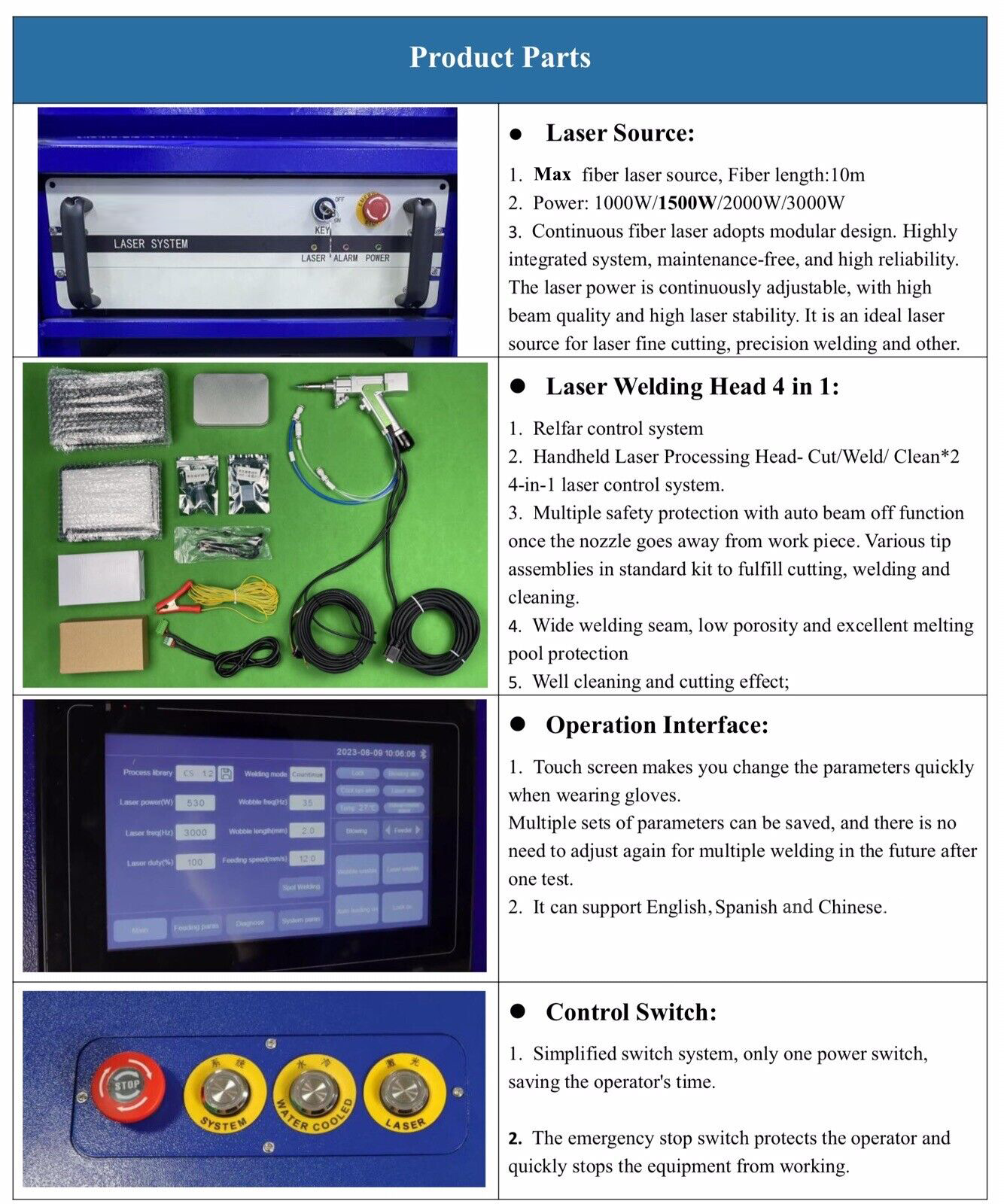

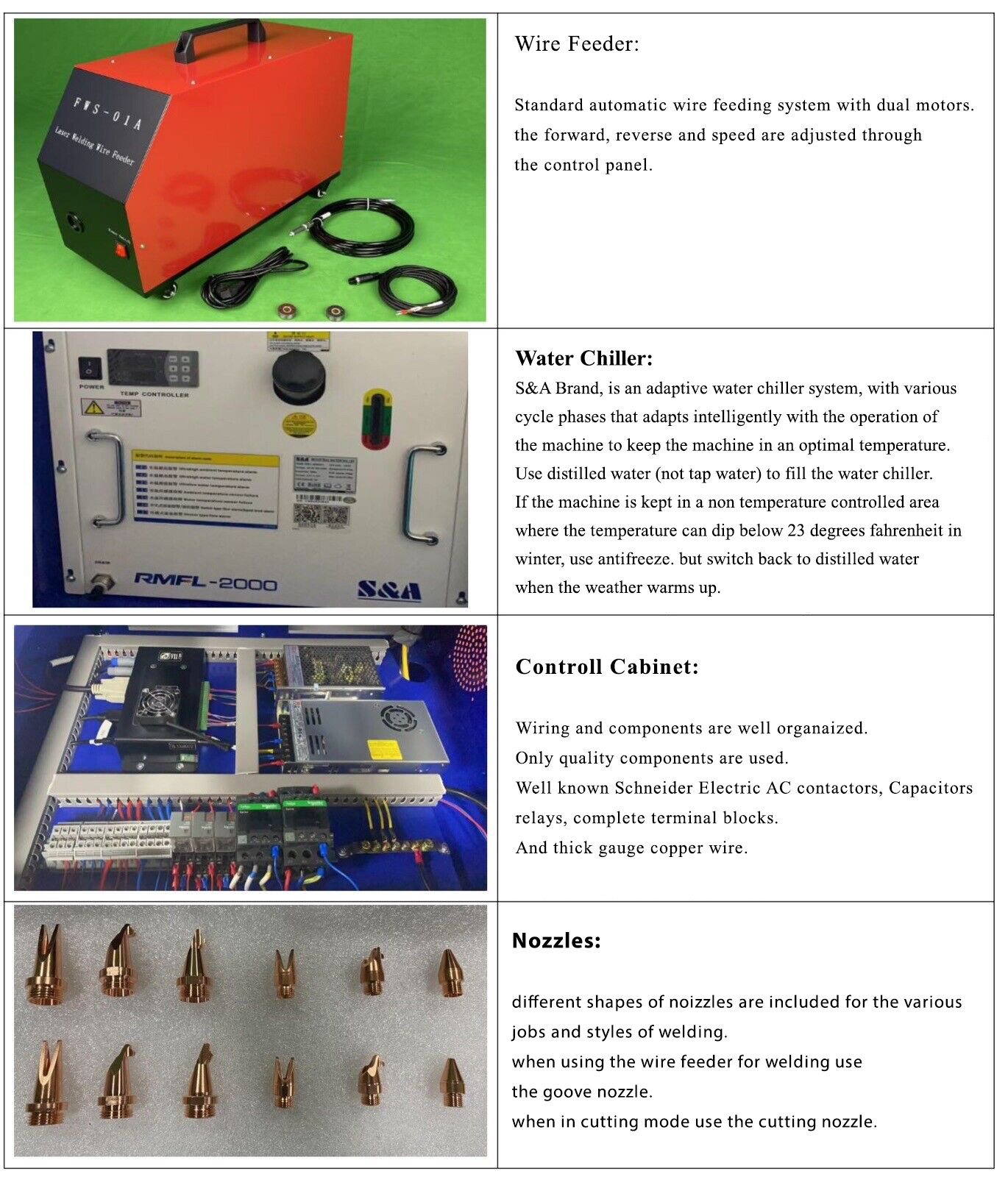

Maxware Industrial Equipement Introduces the 2000W Laser Welder, the ultimate solution for your welding needs! This laser welding machine is equipped with advanced fiber laser technology that ensures precise and efficient welding, cutting, and cleaning of various materials. The unit is manufactured in China and comes with a variety of accessories to make your welding experience seamless.

Metal cleaning

- Metal cleaning becomes a fun process with this machine, no need for sand blasting, DA sanding or wire brush and you don't have to wait hours for toxic chemicals to remove some rust. Laser rust / paint removal is so quick it saves valuable work time and reduces fatigue drastically. laser metal cleaning is non-evasive and does not damage the surface of the material.

We also offer a Specialized Cleaning Machine that offers a 12-inch-wide cleaning beam as opposed to the 3 inch beam that comes with the 4in1 machine welding machine. If your work routine is comprised mostly of metal cleaning, then we highly recommend the specialized cleaning machine that is designed specifically to do one task and do it perfectly. The specialized cleaning machine looks exactly the same as the 4in1 welding machine but has a specialized cleaning gun. The price is the same as the 4in1 welding machine. If you prefer the specialized cleaning machine, please add a note "specialized cleaning machine" when you place an order.

Metal cutting

- Metal cutting is elevated to whole new level with the precision of fiber laser cutting ability, so no need for cutting wheels, and the precision is far superior to plasma cutting.

Laser Welding

-Laser Welding is making great impact in the industry thanks to the new technology that makes welding a lot easier, less messy, and way more precise. The welds penetrate the metal without damaging it. The end results are strong professional looking welds.

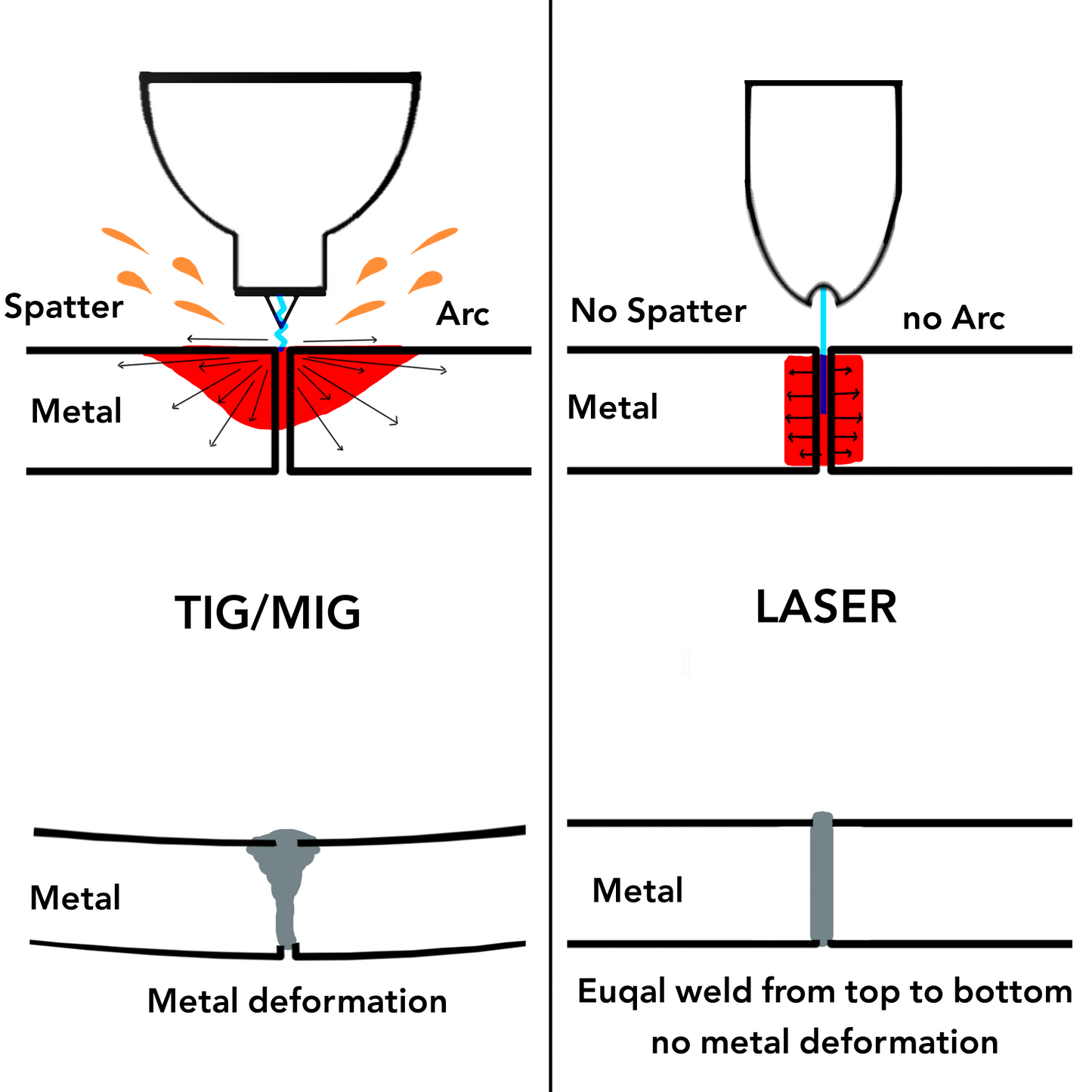

The difference between laser welding and arc welding is big. Arc welding uses electron to heat up the surface of the material, the heat propagates on the surface before it penetrates the material which causes material deformation. The percentage of energy wasted with TIG/MIG is very high. Laser welding on the other hand uses light (photons instead of electron) that welds the metal from the center-out which makes surface contaminate a lesser problem in welding. In addition, the energy density of laser is 200 times higher than MIG/TIG, which makes Laser welding very effective with minimum amount of electricity used. When laser penetrate the metal the heat produced by the refracting light gets equally distributed between top and bottom surfaces, which makes laser welds much superior than the traditional method. Laser welding produces no splatter which makes the welding enivrement safer for the operator. laser welder does not produce arc either, so you dont have to worry about arc stability and also eliminate UV Sunburn. Laser welding is less brighter than TIG/MIG which allows to set the welding helmet to a lower shade.

Laser welding is faster, stronger and easier than traditional welding.

Weld cleaning

-Weld bead cleaning is a bonus feature that’s not always used since welds come out great with fiber laser.

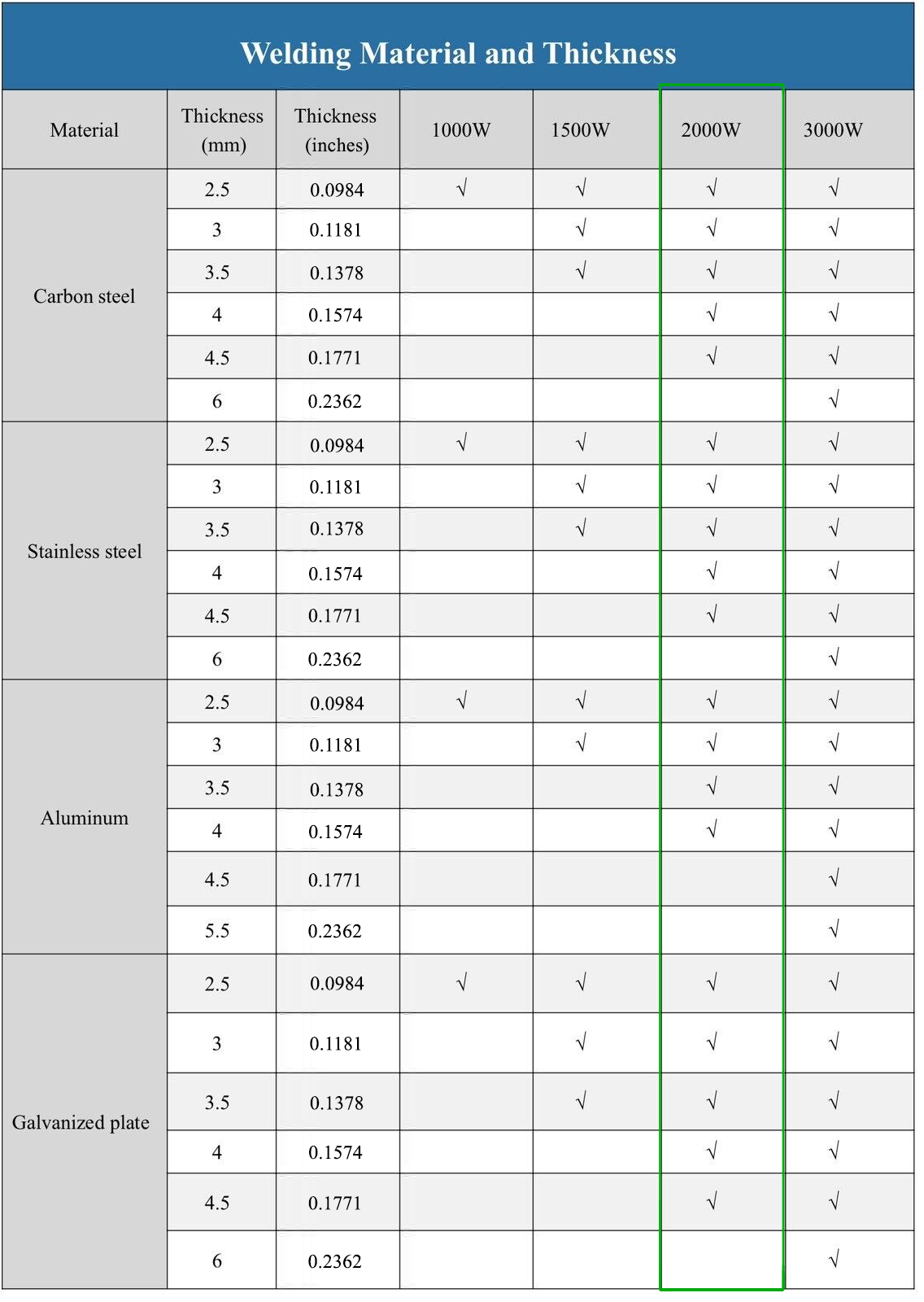

You can weld steel (Carbon steel), Stainless steel, Aluminum, and Galvanized steel with this machine

In contrast to the Pulse Type Laser Cleaning Machine, the Continuous Fiber Laser Cleaner is better suited for applications demanding high efficiency. It finds use in various industries such as aviation, marine/ship makers, metal fabrication, wrought iron welding, rubber mold making, equipment manufacturing, construction, auto parts, Autobody shops, Metal fabrication shops, pipeline welders, Structural engineers, boilermakers. metal sculpture artists, food processing, automated welding robot arms and much more.

Common applications include rust and paint repair for classic cars/trailers, removing rust from steel constructions, graffiti removal, cleaning metal parts, de-rusting components, decontaminating gears, removing paint from castings, cleaning weld seams, stripping and removing paint, as well as rust and corrosion removal.

The 2000W Laser Welder is ideal for use in business and industrial settings and is perfect assistant. This product is a one-stop solution for all your welding needs. Get your hands on the most advanced laser welding technology today!

Specs:

Machine weighs 260lb and will be shipped with freight forwarder in a crate with a gross weight of 330lb.

The box measures 52in x 52in x 29in

The machine requires 220V Single Phase - 45Amps-50Amps. 10KW

Shipping by sea from China to the US typically takes approximately 5 weeks to 6 weeks via sea freight. At our facility, our machines are not mass assembled; instead, upon receiving a purchase order, each one is meticulously assembled and tested by our certified technicians. To facilitate a smooth delivery process, we kindly request that you provide a accurate phone number and current address when placing your order, this allows the shipper to coordinate a convenient delivery date and time. While sea shipments may experience delays, they always arrive safely. Tracking will be provided once pallet clears US customs and gets to a distribution center. Customs clearance and duty fees are taken care of by us, there are no hidden costs or additional charges. Please note that a signature will be required upon delivery.

Feel free to ask any question I'd be happy to assist.

Share